Services

Process Engineered Solutions

With a team of specialist engineers and project managers, BCD deliver bespoke process engineering solutions to the Life Science and Food & Beverage sectors.

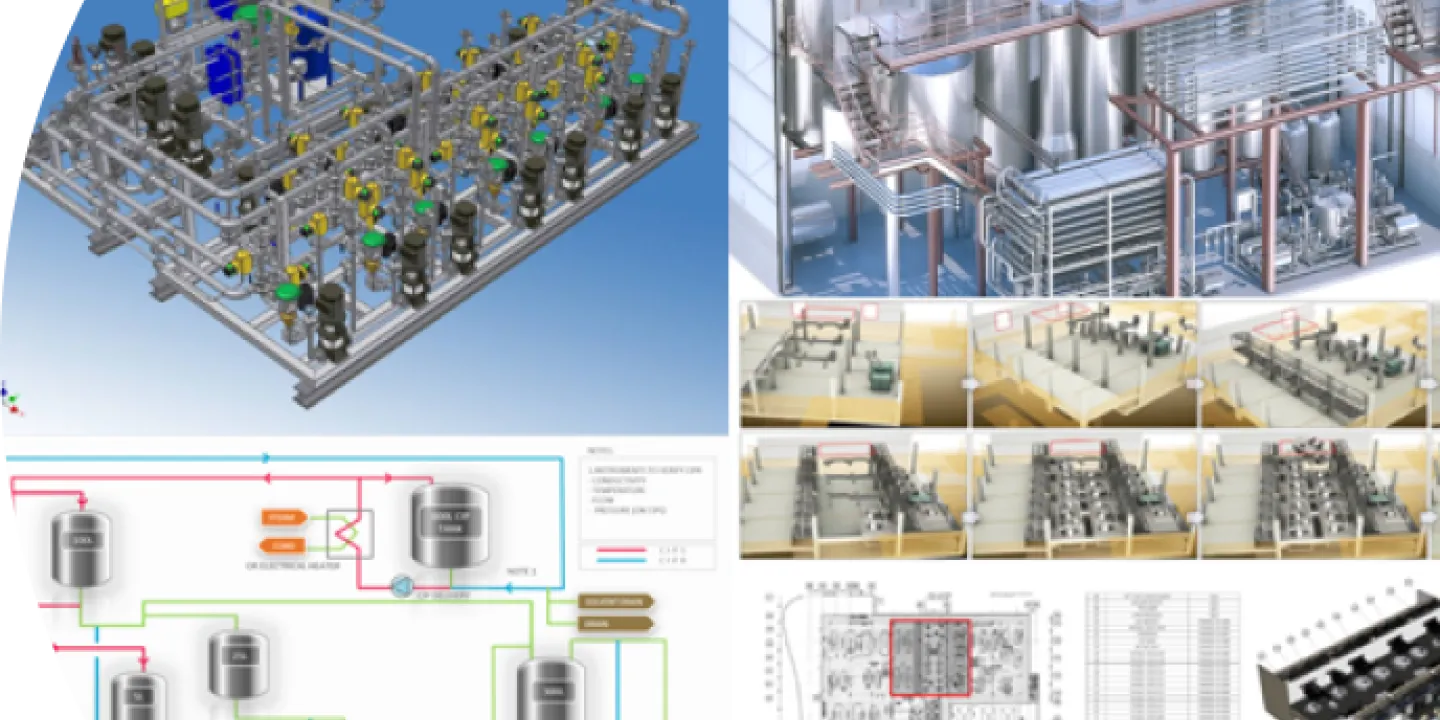

Process Design

Our Process Engineering team can develop a process solution, or work with our customers to optimise an existing design. They will also develop a complete equipment list, along with equipment specifications, for all the process equipment and instrumentation.

3D Modelling and Mechanical Design

Our Mechanical and Electrical Engineering team will develop layout drawings in 3D, to ensure all issues with construction and equipment ingress are resolved long before the construction phase starts.

Procurement and Supply Chain Management

Our Procurement team will ensure all the equipment and raw materials are on site in BCD's workshops, to ensure the manufacture of the required solution can proceed in line with the project schedule.

Fabrication and Assembly

BCD's fully qualified workshop team, working closely with their project management, engineering, procurement and compliance colleagues will fabricate and assemble the final process solution and ready the system for the factory acceptance test (FAT)

FAT

The entire Engineering team, together with the project manager, the Health & Safety and Quality & Compliance teams, will work with the customers' representatives to complete all the actions required for the factory acceptance test (FAT).

Installation and Commissioning

Finally, the solutions will be delivered to site, and installed under the supervision of the BCD team. This team will also undertake the commissioning of the system ahead of the SAT and final handover.

SAT and Final Handover

BCD will work with the customer's team to complete the site acceptance test (SAT). This will include any necessary IQ, OQ, PO checks and paperwork, plus user documentation, before final handover to the customers' production team.